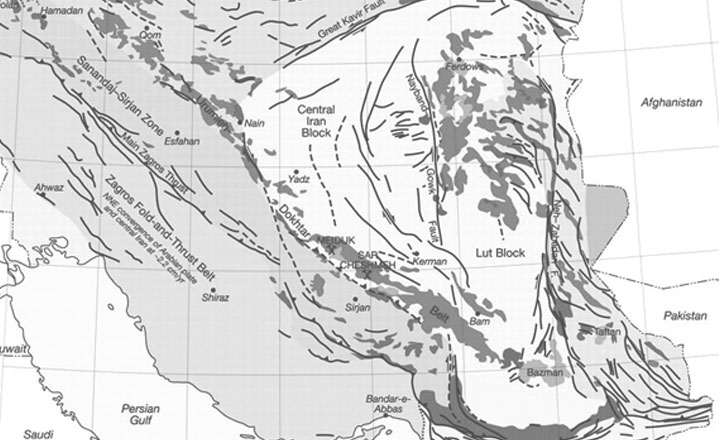

GolGohar Iron Ore Co is located in southern Iran, 50 km from Sirjan, in southwest of Kerman Province (latitude 29°7′N and longitude 55°19′E) surrounded by mountains over 2500 m high. In 1969, GolGohar Iron Ore deposits were discovered by Iran Barite Company. GolGohar follows a mining tradition in this region which dates back 900 years.

GolGohar Mines contain 6 ore bodies spread over an area of 40 square km. The total deposits of iron ore in the region are estimated to be over 1.135 billion tons. The major ore body has a deposit of more than 650 million tons. GolGohar is connected to the Trans-Iranian Railway through the Tehran-Bandar Abbas line At GolGohar, 6 million tons per year of concentrate is produced through crushing, dring and wet grinding, and magnetic separation methods using low intensity magnetic separators. Dry magnetic separation extracts 65% of the final product and the rest is obtained by a process of wet magnetic separation.

A concentrate production line to process an additional 2.5 million tons per year of is under construction and will be in operation in the near future. The construction of a 5 million ton/year pelletizing unit next to existing installations was recently completed and is currently commencing production.

Petrographic and geochemical studies of metaplite and amphibolite units show that those were marl and shale sedimentary rocks that are metamorphed and mylonitization to mid- amphibolite facies during early Cimmerian orogeny and no relationship with deposit genesis. Iron ore mineralization has happened simultaneously and after Gol-Gohar complex deposition and pyrite mineralization after creating iron oxide. Talc, serpentine and clinochlore are gangue main minerals in association with magnetite. Serpentine of olivine metasomatism, talc of serpentine alteration and clinochlore has been created during retrograde changes of reaction aluminum-bring fluids with the serpentine. Comparison of main, trace and rare-earth elements of Gol-Gohar iron ore with other iron deposit of the world and Iran shows it is similarities with the volcano-sedimenter and skarn iron type and most diagrams normalized REE shows same trend with deposits as magmatic fluids origin. Carbon and oxygen isotope investigation on deposit breakers carbonate veins that have often dolomitic composition shows for thier low temperature hydrothermal origin. Acording to the results of these studies is argued that Gol-Gohar iron ore has been formed during two stages as follows: first stage- the iron-bring fluids enter to sedimentary basin and deposition of iron ore to form of volcano-sedimenter type, simultaneous with Gol-Gohar complex. The second stage-during Neotethys ocean subduction and early Cimmerian orogenic operation, all set of first stage is affected amphibolite facies metamorphism. Pay attention to granite intrusions existence in the South of Gol-Gohar ore deposit and also in drilling core within ore body seems along with orogenic and mass intrusive enter has lead to iron ore re-creating or iron-bring fluids re-rotation in dolomitic units and Mg-skarn (olivine, talc and serpentine) formation. Finally, green schist retrograde facies has effect of the region total and has been causing the formation of chlorite and epidote minerals in Gol-Gohar complex and clinochlor in iron ore.

A brief statistical guide to the GolGohar area:

- Height above sea level : 1750 m

- Average annual rainfall : 120 mm

- Highest temperature recorded: : + 40 degree Celsius

- Lowest temperature recorded : - 16 degree Celsius

- Max. Wind Speed : 65 km/h

- Average humidity: +30

As of June 21,2010 the company is owned by the following share holders:

- Omid Investment Management Corporation : 39.02%

- Mines & Metals Development Investment Company : 23.75%

- Mobarakeh Steel Company : 6.46%

- Civil Servants Pension Fund : 2.80%

- Mehregan Investment Co. : 3.75%

- Oil Pension Fund Investment Co. : 3.62%

- Others : 20.6%

- Total Shares : 100%

Extraction activities in the Gole-Gohar mine

A View of Gole-Gohar mine bench face

A Picture of Gole-Gohar mine ore

Ore transport by mine machinery