Get In Touch

|

Unit No. 1403, 14th Floor, Negin Reza tower, Ashrafi Esfahani Expy, Tehran, Iran. +98 21 4403 1818 +98 21 4406 3628 This email address is being protected from spambots. You need JavaScript enabled to view it. |

Mining in Iran 2 (17)

The Sari Gunay deposit is one of the largest gold deposits in Iran and this area which is located in ENE of Qorveh and south of the study area. This deposit is an isolated one in complexes of Miocene magmatism. The component units of this deposit are complexes of igneous rocks which include latite, dacite, rhyolite and subvolcanic stocks (microgranite and microgranodiorite) with high K subalkaline (Richards et al, 2006). This complex is located unconformably over the Triassic-Jurassic schist and limestones and toward north and south and west it goes beneath quaternary alluvium and has a little outcrop. The main difference between this deposit in Qorveh area and other deposits in the Takab area is the absence of early Miocene magmatism which points to the fact that intensity of upwelling in this area is not as high as Takab. Therefore high intensity of upwelling and extensional regime relevant to them in Takab area is the main factor in production of early Miocene magmatism. The geometry of ore in this deposit is mainly crosscuting, vein, veinlets and disseminated ore which are located in fractures with NNE trending and altered margins. The main alteration in this deposit includes chloritization, sericitization, silicification, tourmalinization and K-feldspar.

Aghdarreh

Written by Super UserThe Aghdarreh deposit is the second largest deposit (~25t Au) in Takab that is located in 1.4 km WSW Zarshuran deposit in north of this area. Although the sequence of basinal rocks in which Aghdarreh is located is similar to Zarshuran deposit but in Aghdarreh the distribution of outcrops is not as varied as in Zarshuran.

Gold mineralization is invisible in jasperoids and enriched in hydroxides of Fe-Mn in surface and mineralization is accompanied with elements such as As, Sb, Hg, Te, Se, Tl, Ba, Zn, Ag, Cd, Bi, Pb and is characterized with little contents of Cu (Daliran, 2007).

Age of mineralization in this deposit based on similarity of mineralogy and adjacency with Zarshuran, existence of Miocene volcanism in the nearest distance in Zarshuran deposit and data of Zarshuran dating, has been considered 14.2 Ma similar to Zarshuran.

It is located 40km northeastern Takab and 6km north of Zarshuran Village. Mineral area was preciously exploited for arsenic. Gold mineralization has occurred with As in carbonate rocks and the deposit is carline like deposit. Zonal lithology consists of upper Proterozoic metamorphic rocks including serpentinite schist, amphibolite and ultramafic rocks (Iman Khan complex), upper Proterozoic limestone (Chaldaq unit), which overlay the former, rocks gradually or by disconformity contact, succession of black coal bearing shale and limestone which contains As mineralization (Zarshuran Unit), Shale and gray sandstone of Barut, Zagoon and Laloon Formations, Oligomiocene Qom Formation, Upper Red Formation (sandstone, conglomerate, alluvial deposits).

Ore mineralization of Zarshuran Deposit has occurred in the contact of black coal bearing layer and old metamorphic rocks. The main ore body situated between the unconformity boundaries of lower Miocene with crystalline basement and some of the ore is available down into the basement rock. Gold has fine grain and scale form. Gold grade is 7-10 ppm which detailed exploration of the deposit displays 40 tons gold reserve. It seems that mineralization is epithermal type that is the result of young volcanic activities that mineralized the Chaldaq and Zarshuran units.

The lead and zinc beneficiation plant at Dandi with a capacity of about 140 tons per hour is located 100 km southwest ofZanjan town. Oxidized lead- and zinc ore from the Anguran mine (situated at a distance of 20km from the plant) is used as the feed for this plant. The primary minerals of this mine are cerussite and smithsonite. The plant has been designed to handle two types of feeds i.e. low- and high grade zinc ores. The plant has been equipped and installed from1973-1979. The high grade ore contains 10% lead and 35% zinc while the low grade ore averages 7% lead and 22% zinc. The normal products of the plant include lead concentrate grading 60% lead, zinc concentrate with 38% zinc and a calcined zinc concentrate with 52% zinc. This plant includes the following sections: rock crushing, HMS, milling, filtration and calcination. If the feed is of the low-grade type, it is first upgraded by HMS cyclones and the concentrate obtained is introduced along with the high grade feed into the milling circuit and subsequently concentrated in the flotation unit. Material <2mm in size which is not introduced into the HMS circuit, is milled and added to the low grade flotation route. Finally, after the rougher, cleaner and scavenger stages of the lead flotation route, a concentrate with 60% lead is obtained and the corresponding tailing is dewatered and sent to the zinc concentrate stockpile. A part of the zinc concentrate is sent to the calcination unit to obtain a calcined product containing 52% zinc.

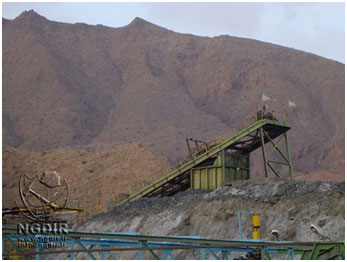

Kushk Lead and Zinc mine situated at 165 km far from east of Yazd and 45 km of northeast of Bafgh Township at Lut desert margin. This mine use underground method in its extraction and certain Lead and Zinc reserves of the mine has been estimated 2997000 tons with 14 % carat.

mine installations

mine underground tunnel

Picture of ore carrier wagons

The lead and zinc beneficiation plant at Dandi with a capacity of about 140 tons per hour is located 100 km southwest of Zanjan town. Oxidized lead- and zinc ore from the Anguran mine (situated at a distance of 20km from the plant) is used as the feed for this plant. The primary minerals of this mine are cerussite and smithsonite. The plant has been designed to handle two types of feeds i.e. low- and high grade zinc ores. The plant has been equipped and installed from1973-1979. The high grade ore contains 10% lead and 35% zinc while the low grade ore averages 7% lead and 22% zinc. The normal products of the plant include lead concentrate grading 60% lead, zinc concentrate with 38% zinc and a calcined zinc concentrate with 52% zinc. This plant includes the following sections: rock crushing, HMS, milling, filtration and calcination. If the feed is of the low-grade type, it is first upgraded by HMS cyclones and the concentrate obtained is introduced along with the high grade feed into the milling circuit and subsequently concentrated in the flotation unit. Material <2mm in size which is not introduced into the HMS circuit, is milled and added to the low grade flotation route. Finally, after the rougher, cleaner and scavenger stages of the lead flotation route, a concentrate with 60% lead is obtained and the corresponding tailing is dewatered and sent to the zinc concentrate stockpile. A part of the zinc concentrate is sent to the calcination unit to obtain a calcined product containing 52% zinc.

The Sangan Fe deposit is located about 18 km NE of Sangan town in Central East Iran (Khorasan Province) and about 500 km NNE of Bafq. The Sangan deposit contains ~500 Mt of high-grade Fe-oxide reserves and is divided into the east, west and central ore bodies. The ore is hosted by carbonates associated with felsic volcanic and intrusive rocks including rhyolite, trachyte, dacite, andesite, granite and monzonite. The granites have a calc-alkaline geochemical signature. The main ore mineral is magnetite with minor hematite, pyrite, chalcopyrite and pyrrhotite. Two types of skarn have been recognised; a Ca-skarn containing garnet, clinopyroxene, calcite, quartz, amphibole, epidote, scapolite and dolomite bearing assemblages and Mg-skarn with forsterite, phlogopite, serpentine, clinochlore, amphibole, talc, magnesite, chlorite, calcite and sulphides (Ebrahimizadeh, 1995). Bagherian Kalat (1996) suggest that the main mineralizing stage is associated with hydrothermal activities that followed the primary stage of skarn development. Giere and Mohammadi (1977) describe the ore body as pipe-like, with signs of an explosive emplacement. Kermani and Forster (1991) proposed that the ore at Sangan crystallised from a Fe-rich magma.(JAMI, 2005)

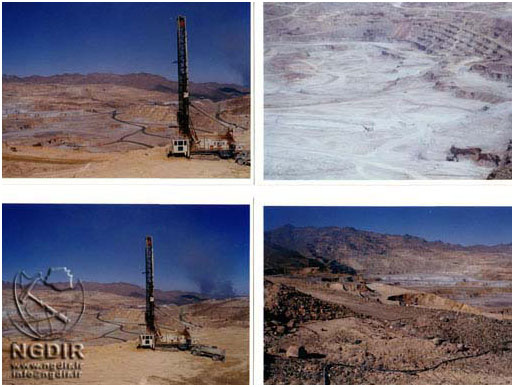

Wagon drill

View of Sangan mine bench face

Picture of Sangan mine bench face

View of extraction activities by exploration equip

View of Sangan mine

GolGohar Iron Ore Co is located in southern Iran, 50 km from Sirjan, in southwest of Kerman Province (latitude 29°7′N and longitude 55°19′E) surrounded by mountains over 2500 m high. In 1969, GolGohar Iron Ore deposits were discovered by Iran Barite Company. GolGohar follows a mining tradition in this region which dates back 900 years.

GolGohar Mines contain 6 ore bodies spread over an area of 40 square km. The total deposits of iron ore in the region are estimated to be over 1.135 billion tons. The major ore body has a deposit of more than 650 million tons. GolGohar is connected to the Trans-Iranian Railway through the Tehran-Bandar Abbas line At GolGohar, 6 million tons per year of concentrate is produced through crushing, dring and wet grinding, and magnetic separation methods using low intensity magnetic separators. Dry magnetic separation extracts 65% of the final product and the rest is obtained by a process of wet magnetic separation.

A concentrate production line to process an additional 2.5 million tons per year of is under construction and will be in operation in the near future. The construction of a 5 million ton/year pelletizing unit next to existing installations was recently completed and is currently commencing production.

Petrographic and geochemical studies of metaplite and amphibolite units show that those were marl and shale sedimentary rocks that are metamorphed and mylonitization to mid- amphibolite facies during early Cimmerian orogeny and no relationship with deposit genesis. Iron ore mineralization has happened simultaneously and after Gol-Gohar complex deposition and pyrite mineralization after creating iron oxide. Talc, serpentine and clinochlore are gangue main minerals in association with magnetite. Serpentine of olivine metasomatism, talc of serpentine alteration and clinochlore has been created during retrograde changes of reaction aluminum-bring fluids with the serpentine. Comparison of main, trace and rare-earth elements of Gol-Gohar iron ore with other iron deposit of the world and Iran shows it is similarities with the volcano-sedimenter and skarn iron type and most diagrams normalized REE shows same trend with deposits as magmatic fluids origin. Carbon and oxygen isotope investigation on deposit breakers carbonate veins that have often dolomitic composition shows for thier low temperature hydrothermal origin. Acording to the results of these studies is argued that Gol-Gohar iron ore has been formed during two stages as follows: first stage- the iron-bring fluids enter to sedimentary basin and deposition of iron ore to form of volcano-sedimenter type, simultaneous with Gol-Gohar complex. The second stage-during Neotethys ocean subduction and early Cimmerian orogenic operation, all set of first stage is affected amphibolite facies metamorphism. Pay attention to granite intrusions existence in the South of Gol-Gohar ore deposit and also in drilling core within ore body seems along with orogenic and mass intrusive enter has lead to iron ore re-creating or iron-bring fluids re-rotation in dolomitic units and Mg-skarn (olivine, talc and serpentine) formation. Finally, green schist retrograde facies has effect of the region total and has been causing the formation of chlorite and epidote minerals in Gol-Gohar complex and clinochlor in iron ore.

A brief statistical guide to the GolGohar area:

- Height above sea level : 1750 m

- Average annual rainfall : 120 mm

- Highest temperature recorded: : + 40 degree Celsius

- Lowest temperature recorded : - 16 degree Celsius

- Max. Wind Speed : 65 km/h

- Average humidity: +30

As of June 21,2010 the company is owned by the following share holders:

- Omid Investment Management Corporation : 39.02%

- Mines & Metals Development Investment Company : 23.75%

- Mobarakeh Steel Company : 6.46%

- Civil Servants Pension Fund : 2.80%

- Mehregan Investment Co. : 3.75%

- Oil Pension Fund Investment Co. : 3.62%

- Others : 20.6%

- Total Shares : 100%

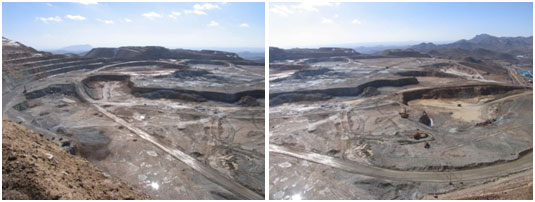

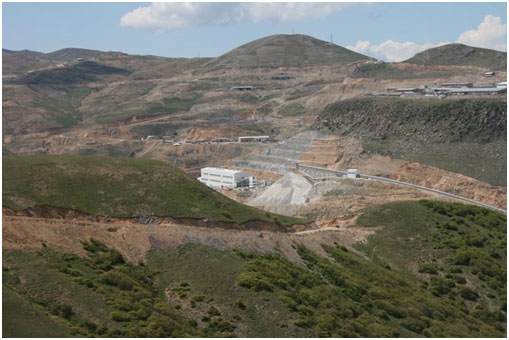

Extraction activities in the Gole-Gohar mine

A View of Gole-Gohar mine bench face

A Picture of Gole-Gohar mine ore

Ore transport by mine machinery

The origin of the Proterozoic Choghart iron oxide deposit in the Bafq mining district of Central Iran has been the subject of a long-standing dispute. Some authors believe that it was formed from magma, while others suggest metasomatic replacement of preexisting rocks. The present study on the basis of new oxygen isotope, REE and geochemical data concludes that neither of these two hypotheses can alone explain the formation of Choghart deposit. Instead, it is suggested that the separation of an iron oxide melt and the ensuing hydrothermal processes dominated by alkali metasomatism were both involved to different degrees in the formation of Choghart and other similar deposits in Central Iran.

MOORE & MODABBERI.

Choghart Iron Deposite is one of the largest iron ore mines of Iran, which is located in the northeast of Bafgh-Yazd. The minable reserve is more than 170 million tons. This mine is extracted by surface mining method.

Mining operations usually include the five stages of drilling, blasting, loading, hauling and crushing. Loading and Transporting is done with truck-Shovel system.

Drilling and blasting operations are so important, because of some reasons such as: complex discontinuity system existence, the rock type variations and the water bearing beds.

- Choghart Mine Characteristics:

- Shape and Size of pit: Ellipse (840m Long Diagonal & 640m Width Diagonal)

- Stripping ratio: 0.85

- Highest Level: 1140 m

- Pit Depth: 327.5 m

- Overall Slope Angle: 55 degree

- Bench Height: 10 m (from 1140 to 1100 level), 12.5 m (from 1100 to 812.5 level)

- Shovel capacity: 7.6 m3

- Truck capacity: 85 ton

- Ore Specification: ( Fe: 66% & P: 0.12% )

- Chaghart Expansion Project

Objects of this Choghart Expansion Project, which has been started since 1989, are:

- To secure the supply of 3 Mt/y of suitable DSO feed (Direct Shipping Ore) for Blast Furnace

- To produce 3.2 Mt/y Iron concentrate as feed to Agglomeration Plant.

Due to existence of differences between the mined ores from Choghart and Sechahoun mines, two separate processing lines have been considered.

- Choghart Beneficiation Plant

A 3.2 Mt/y fine concentration beneficiation plant consisting of two independent process lines, as below:

- Choghart Process Line, with the feed capacity of 2.3 Mt/y produce 1.6 Mt/y fine concentrate

- Choghart production line

The mined low grade high phosphorous Choghart Iron Ore rocks of about 1000 mm size are crushed to 300mm by a primary jaw crusher.

The crushed ore is then transferred to the stockpiling and reclamation area for mixing and homogenizing. The stockpiling is carried out by a stocker. Then, using reclaimer and a conveyor belt, the stockpiled crusherd ore is delivered to a 2000 tons bin, where it is fed to Autogenous (AG) mill by a vibrating feeder.

The AG mill is in closed circuit with a vibrating screen with 1 mm aperture. The screen oversize returns to the AG mill as recirculating load and the undersize material is fed to the low intensity magnetic separators (LIMS), which consists of two separation stages (Rougher and Cleaner).The rougher concentrate is fed to the cleaner separators. Then the cleaner concentrate is being dewatered by pumping it to the filteration section. The tailing from rougher and cleaner stages is pumped to a hydrocyclone for adjusting its solid content (dewatering), and then it is pumped to scavenger magnetite separators for recovery of its Iron Content. The scavenger concentrate is also being dewatering by filteration. The obtained Iron Ore concentrates are transferred from filteration section to stockpiling area for storage by belt conveyors. And from there, they will be delivered to the loading station.

- Se-Chahoun production line

The mined low grade high phosphorous Choghart Iron Ore rocks of about 1000 mm size are crushed to 300mm by a primary jaw crusher. The crushed ore is then transferred to the stockpiling and reclamation area for mixing and homogenizing. The stockpiling is carried out by a stocker. Then, using reclaimer and a conveyor belt, the stockpiled crusherd ore is delivered to a 2000 tons bin, where it is fed to Autogenous (AG) mill by a vibrating feeder.

The AG mill is in closed circuit with a vibrating screen with 1 mm aperture. The screen oversize returns to the AG mill as recirculating load and the undersize material is fed to the low intensity magnetic separators (LIMS), which consists of two separation stages (Rougher and Cleaner). The rougher concentrate is fed to the cleaner separators. Then the cleaner concentrate is being dewatered by pumping it to the filteration section.

The Bafq metallogenic province hosts major (1.8 Gt) Kiruna-type, sulphide-poor REE-apatite-magnetite (±hematite) deposits that are transitional to apatite-rich rocks, called “apatitites”. The deposits are hosted by volcanosedimentarysequences as well as individual volcanic rocks of dominantly rhyolite-rhyodacite composition that are part of an Early Cambrian volcanism within the Kashmar Kerman magmatic arc in East-Central Iran. The felsic volcanism is part of a felsic-mafic bimodal volcanism of alkaline character with minor andesites and rare undersaturated rocks (nephelinite-basanite) that was followed by a regional, alkali (sodic and potassic) metasomatism, formation of albiterich rocks (albitites), apatite-Fe oxide mineralization, and swarms of late diabase dykes. Multistage metasomatism resulted in the formation of synvolcanic-synsedimentary to synsedimentary epigenetic, and post-volcanic epigenetic mineralization. The ore fluids evolved from an anhydrous paragenetic association consisting of LREE-F(-Cl±OH)-apatite and monazite ± Ca-rich pyroxene, actinolite or chlorite, ±quartz, magnetite(±hematite) ± REE-Ca-rich garnet. Multistage Actinolite is the most common ore-related alteration and formed instead of pyroxene during the early-stage at lower temperatures. Chlorite formed instead of actinolite at lower temperatures. The late-stage fluids were enriched in CO2, SiO2 and HREE and formed calcite, quartz, monazite2, apatite2, allanite, and HREE minerals xenotime, bastnaesite, syncheysite, and britholite. Minor, post-oxide pyrite±chalcopyrite was followed by talc alteration, rutile, Sr-barite, and Ca-thorianite, and by chloritization and sericitization. Anhydrite ±fluorite ±Sr-barite formed with autigenic quartz and feldspars in sedimentary ores. Similar radiometric ages of the ore-related apatite, monazite, and the host rhyolites (525–539 Ma) confirms that the mineralization was coeval with the Early Cambrian high level magmatism, suggesting a direct relationship between the magma generation and the mineralization. Ore-related, large scale metasomatism within the Bafq structural zone, and the association with the bimodal volcanism with alkaline character and an alkali metasomatism indicate a tectonomagmatic control on the mineralization that was probably related to a short lived rifting stage in the Early Cambrian. In the apparent absence of Cu-Au deposits, the Bafq region can be referred as an IOA (Iron Oxide Apatite) metallogenic province.DALIRAN et al., 2010 The Bafq mining district contains >2,000 Mt of high-grade Fe ore (NISCO, 1980), which places it among the largest non-BIF type Fe ore districts of the world. This region has attracted geologists for nearly a century due to its complexity and valuable ore deposits. The Bafq mining district contains significant bodies of magnetite mineralization as reflected by 34 major magnetic targets and several non-Fe systems containingPb and Zn, Mn, U, P and REE. The Fe-oxide deposits of the Bafq region mainly consist of magnetite-hematiteapatite and host by Cambrian volcano-sedimentary sequence (also known as Saghand Formation) associated with number of felsic and mafic intrusions. These ore bodies are commonly associated with pervasively altered rhyolitic tuffs and sandstones. The origin of the Bafq Fe deposits is the subject of a long-standing debate. Among the geological and exploration reports on the region were those of Stahl (1911); Bohne (1928, 1929); Baier (1940); Kumel (1941); Diehl (1944); Walther and Kursten (1958); Venzlaff et al. (1961); Molly (1964) and Iwao and Zahedi (1966). Huckriede et al. (1962) worked on the geology of the Kerman–Bafq region and attempted to classify its Fe ores. The National Iranian Steel Corporation (NISCO) initiated several exploration projects. The results of these investigations were compiled in a series of internal reports. These investigations were oriented toward documenting exploration of the ore field by geophysical exploration and drilling. During these programs over 80 magnetic anomalies were discovered and many of these were subsequently drilled. Based on the information acquired from these works the style of mineralization and the geological setting have been documented by geologists of National Iranian Iron and Steel Corporation. Most of the early authors proposed a metamorphic origin for the Bafq Fe-apatite deposits, although some geologists who mainly worked on the NISCO projects proposed a metasomatic origin involving metamorphism, volcanic and intrusive activity. Williams and Houshmand-zadeh (1966) proposed a magmatic origin for the Choghart deposit and compared it with the Kiruna Fe ore deposits. Investigators supporting an immiscible liquid magmatic model of formation included Forster and Borumandi (1971) and Forster and Jafarzadeh (1984) who reported magnetite lava flows and magnetite-bearing pyroclastic rocks at Chador Malu and suggested a carbonatitic affinity for the Fe-oxide melt (a theme amplified in the account of the Bafq district magnetite–apatite deposits by Forster and Jafarzadeh, 1994). Jafarzadeh (1981) interpretedthe Chador Malu deposit as an explosive vent filled with magnetite melt. Samani (1988a)classified mineralisation at the Choghart mine and at anomalies 20 and 26 as being of magnetite-carbonatite type. Darvishzadeh (1983) and Darvishzadeh et al. (1996) investigated the mineralogical and geochemical characteristics of the Esfordi Fe–P deposit and noted the alkaline affinity of the igneous rocks, the presence of apatite-rich veins, the size and shape of the apatite crystals and the carbonate-rich matrix. Based on the mineralogical association of magnetite, apatite and carbonate it was concluded that there was a relationship between carbonatitic magmatism and mineralisation, although no situ carbonatites were found at Esfordi. Haghipour (1977) wrote a geological and petrological report on the stratigraphic correlation of the Bafq host rocks. He had previously suggested a close relationship between Fe ore deposits and metasomatic metamorphism in some deposits but a volcanogenic or syngenetic origin in other deposits. Similarly, Momenzadeh (1978, 1982, 1986) proposed a syngenetic submarine volcanogenic origin for Bafq region deposits based on their massive, lenticular, banded and lens-like morphology, their development within a specific lithostratigraphic unit and relation to nearby stratified Mn and Pb deposits. Daliran (1990, 1999, 2002) also concluded that hydrothermal fluids played a prominent role in the evolution of the Bafq magnetite–apatite deposits. The significance of some of this work in relation to the Esfordi Fe–P system, particularly that of Daliran (1990, 2002) and Forster and Jafarzadeh (1994) is canvassed in the discussion and conclusion chapter of this thesis.(JAMI, 2005)

Mineral Reserved in Bafgh Region

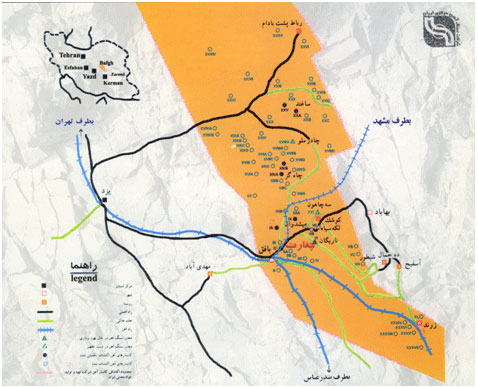

During Infracambrian, some geological activities shaped the Bafgh Volcano Sedimentary Basin. According to these activities, 3 geological iron ore deposits were formed, which are called Bafgh blocks, such as Zarand, Saghand and Robat Poshteh Badam. Potential of Bafgh deposits have been known for a long times, and there are old mine working indicating that some ore was extracted in ancient times. For the first time in 1897 a German geologist (Stahl) identified these deposits and made the geology spot mapping. There are sufficient quantities of valuable minerals such as: Iron Ore, Mg bearing Iron Ore, Apatite, Lead and Zinc in this region. The important minable ore reserves are located at Choghart, Se-Chahoun, Chahgaz, Lakk-E-Siah and North Anomaly

Distribution Map of Bafgh Area Iron Ore Deposits

|

||||||||||||

|

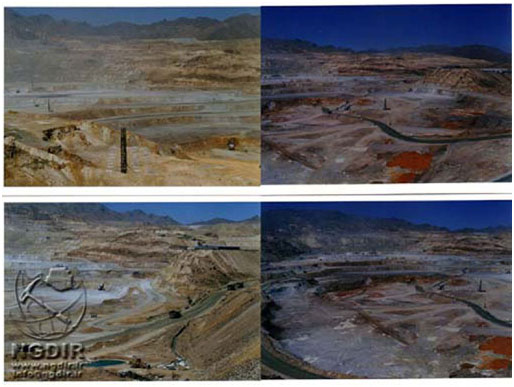

Maiduk copper mine has the distance 42 km to shahr-e-babak city in Kerman province,is located in 132 km of north west of Sar-cheshme copper mine and in mountainous condition with average altitude about 2848 m.

Weather of the area is cold in winter and moderate in summer. Maximim of temperature is 35 ° in summer and minimum is about -15 ° in winter. Maximum of rainfall is about 250 mm annually.

This area is part of the Dokhtar-Orumieh belt that is extended from west to south east of Iran. This mine was used as copper and turquoise mine.

The systematic exploration operation has been done by association of Iranian and foreign companies.

Ore in Maiduk is fungi-form with 350*400 m dimensions that it's upper part of consists of oxide-zone (malachite and azurite mineral) and supergene-zone (mostly culcosite ) Based on exploration done on this project deposit of the mine is estimated to be 170 million tons with average grade 0.83% copper. In last design 144 million tons ore with average grade 0.85% will be mined in 29 years.

Maiduk will mined with open-pit method and wests will carried to dump in around valleys. w/o is 2.4 and overburden is 350 million tons. Annual ore production is 5 million tons. Technical-economical studies done from 1968 to 1994 and primal operation such as road building, power, welfare and services foundations, concentrating factory, dam construction and mine started in 2005.

Client of this project is NICICO-Maiduk copper project. Mobin since 1993 is active in this mine as overburden removal contractor. This company has excavated 113 Million tons from 1993 to 2006 in this mine.

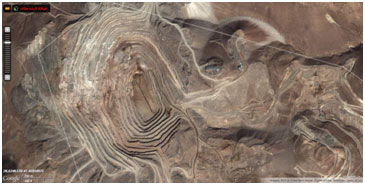

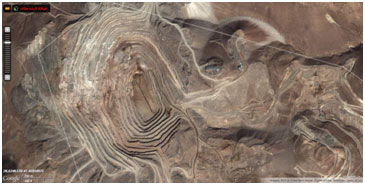

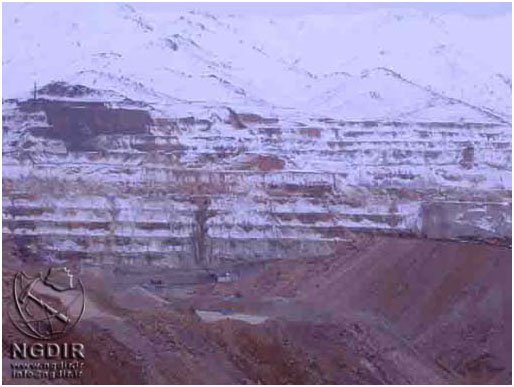

The Sungun copper mine is located in East Azarbaijan, Iran, in Varzaqan county, 75km north west of the provincial town ofAhar. It is the most important geologic and industrial feature in the area and is the largest open-cast copper mine in Iran and is in the primary stages of extraction.

The reserves are estimated to be as much as 995 million tons of copper ore. The ore is processed directly at a concentration plant at the mine. The capacity of the concentration plant is 170,000 tons of copper concentrates, with plans to expand to 300,000 tons.

Sarcheshmehis a large open cast copper mine in the Kerman Province of Iran, considered to be the second largest copper deposit worldwide. Also containing substantial amounts of molybdenum, gold and other rare metals.

The Sarcheshmeh Copper Complex is located 65 km southwest of Kerman and 50 km south of Rafsanjan. The region's altitude averages about 2600m, the highest spot of which approximates 3000m. Sarcheshmeh ore bodies, situated in the central part of Zagros ranges, consist of folded and faulted early tertiary volcano-sedimentary rocks.

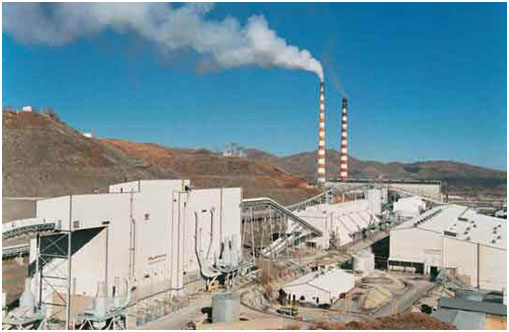

Production units of Sarcheshmeh Copper Complex involve the mine itself, concentrator, smelter, refinery, foundries and leaching.

Accoring to investigation rendered,Iran is located on world copper belt starting from southeasst to northwest of Iran and Azarbaijan. Porphyry copper deposit of Sarcheshmeh is one of the largest of its kind in the world.

Sarcheshmeh copper deposit is situated at 160 Km Southwest of Kerman, 50 Km South of Rafsanjan and at the average altitude of 2,600 Meters and maximum altitude of 3,000 meters. It is located at central Zagros mountain range and is composed of stratified, sedimentary and volcanic rocks and faults pertaining to third geological era. Total Sarcheshmeh ore reserve is about 1.2 billion tons of sulfide ore at the grade of 0.7% Cu.

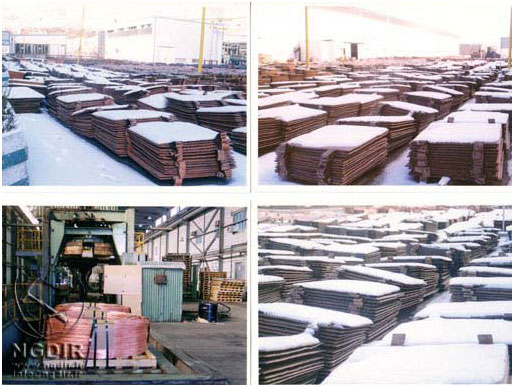

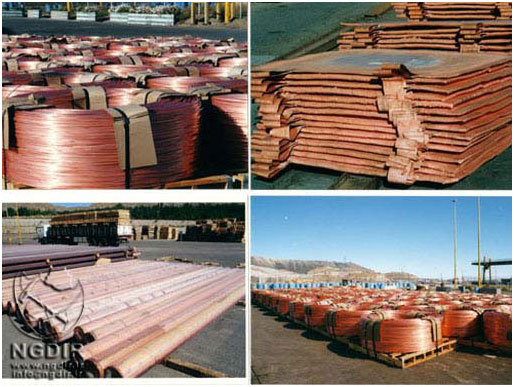

In 1972(1351H.), Sarcheshmeh Copper Mines Joint Stock Co of Kerman was established; and, later, in 1976(1355H.), it was renamed as National Iranian Copper Industries Co to involve all copper mines operations throughout the country. This company has numerous responsibilities to do including extraction and utilization of copper mines, production of copper concentrates and manufacturing copper products such as cathodes, slabs, billets and 8mm wire rods. Sarcheshmeh and Miduk mines in Kerman province and Sunegoon mine in eastern Azarbaiejan province are of the most significant copper mines in the country.

National Iranian Copper Industries Company (NICICO) is involved in exploration, excavation and operation of copper mines in Iran. The company's smelter has an annual production capacity of 145,000 tons of anode copper. The company owns the Sarcheshmeh copper deposit is located in southern Iran, about 65 Km south-east of Rafsanjan. It has a total reserve of 1,200,000,000 MT with an average grade of 0.70 % Cu. Sarcheshmeh porphyry (Granodiorite stock) and peripheral Andesitic volcanics are well mineralized, these series is cutted with post mineralization dykes.

NICICO also owns the Miduk and Sarcheshmeh mines which have proven reserves of 83,830,000 t and 826,500,000 respectively. Miduk produces 5,000,000 t and Sarcheshmeh 14,000,000 t of copper per annum. The Soungoun Ahar mine produces 7,000,000 t of scarn copper grade (0/5 %).

Sarcheshmeh Copper mine located in 160 km of southwest of Kerman and 50 km of south of Rafsanjan. Geological reserve of mine has been estimated over than one milliard and two hundred million tons sulfurous copper ore deposit with 70 % average carat. Additional minerals such molybdenum, gold and silver were found in mine too.

A View of Sarcheshmeh copper mine

A Sample of Sarcheshmeh copper ore

Copper slabs store

Sarcheshmeh copper mine smelt facility

Sarcheshmeh copper company products

A View of wagon drill and Sarcheshmeh copper mine

A View of Sarcheshmeh copper pit

|

Grade |

Ore (M.T) |

Country |

Rank |

|

0.73 |

22011 |

Chile |

1 |

|

0.49 |

14511 |

Peru |

2 |

|

0.39 |

8276 |

Mexic |

3 |

|

0.31 |

10128 |

USA |

4 |

|

0.89 |

3367 |

Indonesia |

5 |

|

2.08 |

1195 |

Poland |

6 |

|

0.79 |

2604 |

Mongolia |

7 |

|

0.58 |

3307 |

Australia |

8 |

|

0.56 |

3289 |

Iran |

9 |

|

0.6 |

2876 |

Kazakhstan |

10 |

|

1.66 |

881 |

Russia |

11 |

|

2.55 |

571 |

Congo |

12 |

|

0.68 |

1838 |

Brazil |

13 |

|

0.49 |

1825 |

Canada |

14 |

|

1.22 |

656 |

Zambia |

15 |

|

0.53 |

1200 |

China |

16 |

|

0.63 |

15978 |

Others |

17 |

|

Cut of Grade (%) |

Average Grade (%) |

Definite and probable reserves |

Name |

|

0.15 |

0.58 |

1538 |

Sarcheshmeh |

|

0.15 |

0.61 |

176 |

Miduk |

|

0.15 |

0.60 |

846 |

Sungun |

|

0.15 |

0.36 |

186 |

DarAlu |

|

0.15 |

0.41 |

149 |

Chah Firuzeh |

|

0.15 |

0.3 |

73.86 |

Eju |

|

0.2 |

0.42 |

134.3 |

Darehzar |

|

0.15 |

0.4 |

130 |

Dareh Zereshk |

|

0.15 |

0.26 |

527 |

Nowchun |

|

0.15 |

0.3 |

204 |

Masjed Daghi |

|

- |

0.59 |

39 |

Kahang |

|

0.25 |

0.23 |

155 |

Haft Cheshmeh |

There are 39 copper mines in Iran:

- Kerman: 14 mines

- Zanjan: 5 mines

- East Azarbaijan: 4 mines

- Other mines are in Qazvin, Semnan, Yazd, Qom,Sistan and–Bloochestan, Khorasan, Markazi and …

17 mines of them are active that the most prominent of them are Sarcheshmeh (826 M.T - 1.2 billion tons), Sungun (440 M.T.) and Miduk (144 M.T.)

The main types of copper deposits in Iran are porphyry and vein deposits.

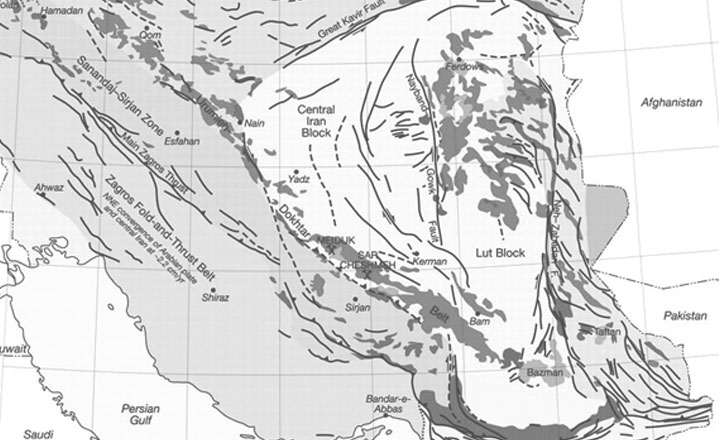

Copper anomalies of the structural zones in Iran are:

- Urmieh- Dokhtar Zone:

- Southern (Kerman)

- Central (Anarak)

- Nothern (Tafresh- Takab)

- Tarom- Taleghan (Karaj to Zanjan)

- Seilan (Ahar)

- Kavir- Sabzevar (Semnan, Torood and Sabzevar)

- Eastern Iran

- Makran

Industry and Mining map of Iran.

Mining in Iran is underdeveloped. Yet the country is one of the most important mineral producers in the world, ranked among 15 major mineral rich countries, holding some 68 types of minerals, 37 billion tonnes of proven reserves and more than 57 billion tonnes of potential reservoirs. Mineral production contributes only 0.6 per cent to the country’s GDP. Add other mining-related industries and this figure increases to just four per cent (2005). Many factors have contributed to this, namely lack of suitable infrastructure, legal barriers, exploration difficulties, and government control over all resources.

The most important mines in Iran include coal, metallic minerals, sand and gravel, chemical minerals and salt. Khorasan has the most operating mines in Iran. Other large deposits which mostly remain underdeveloped are zinc (world's largest), copper (world's ninth largest - revised from second largest in 2010), iron (world's ninth largest), uranium (world's tenth largest) and lead (world's eleventh largest). Iran with roughly 1% of the world's population holds more than 7% of the world's total mineral reserves.

Economics

Close to 30 percent of the country’s investment has been made in the mining field in recent years. In 2008, forty five percent of the stock market's capitalization was in the mineral industries. In 2008 the share of the mining sector and mineral industries increased to over five percent in GDP. The sector with the highest profit margin among the top 100 Iranian companies in 2009 was mining, with a margin of 58%, while those in the Fortune 500 had a gross profit margin of 11%. In the first quarter of 2009–2010, Iran exported close to 5.6 million tons of mineral products worth over $1.2 billion. In 2009–2010 the mining sector had exports reaching $8.13 billion, accounting for about 32 percent of the country’s non-oil exports. Every year, the iron ore price is determined by the government after negotiations between iron ore and steel producers. In 2008, the average price of iron ore was set at $56 per tonne. The steel, cement and iron ore prices are currently being liberalized in Iran. In March 2012, the Iran Mercantile Exchange (IME) announced the complete liberalisation of the sale price of raw steel and by-products.

In 2005, of 3,125 operating mines, 2,747 and 378 mines were run by private and public sectors respectively. As of 2010, 5,574 mines are being exploited in 30 provinces of the country (which are active, inactive or in the state of being equipped). The rate of extraction from these mines stood at approximately 217.5 million tons in previous years. More than 100,000 people are presently engaged in the mines sector while as a whole some 500,000 people are employed in the mine sector. The number of operating mining units stands at 20,375. National Iranian mining company is the world's 23rd largest mining company with 0.6% of the world's total mining production.

Exploration projects implemented by the National Geology and Mineral Exploration Organization in the three years period of 2005–2008 are six times higher than the figure for the same period during the previous government. Since 2005, mortality rate in mining mishaps has declined to one death for every 10 million tons of mining production from the previous figure of six million tons.

Commodities

Although the petroleum industry provides the majority of economic revenues, about 75 percent of all mining sector employees work in mines producing minerals other than oil and natural gas. These include coal, iron ore, copper, lead, zinc, chromium, barite (world's sixth largest producer), salt, gypsum, molybdenum, strontium, silica, uranium, and gold (most as a coproduct of the Sar Cheshmeh copper complex operations). The mines at Sar Cheshmeh in Kerman Province contain the world's second largest lode of copper ore (5% of the world's total). Some 128,500 tons were extracted in 2000–2001. Large iron ore deposits exist in central Iran, near Bafq, Yazd, and Kerman.

Iran produces orpiment and realgar arsenic concentrates, silver, asbestos, borax, hydraulic cement, clays (bentonite, industrial, and kaolin), diatomite, feldspar, fluorspar,turquoise, industrial or glass sand (quartzite and silica), lime, magnesite, nitrogen (of ammonia and urea), perlite, natural ocher and iron oxide mineral pigments, pumice and related volcanic materials, caustic soda, stones and decorative stones (including granite, marble, travertine, dolomite, and limestone), celestite, natural sulfates (aluminum potassium sulfate and sodium sulfate), amber, tungsten, agate, lapislazuli and talc. Iran also produces ferromanganese, ferromolybdenum, nepheline syenite, demantoids, phosphaterock, selenium, shell, andalusite, rockwool, garnet, gabbro, diorite, vermiculite, attapulgite, calcium, barium, rare earth elements, scandium, yttrium and zeolite, and had the capacity to mine onyx.

Iron and Steel

Iron ore

In 2009 Iran will produce 25.5 million tons of iron ore (fines, lumps and concentrate),– Alternatively, U.S. Geological Survey ranked Iran, the 8th largest producer of iron ore in 2009 with 33 million tons of output. Chadormalu and Gol Gohar Iron Ore are the two largest iron ore mines (accounting for more than 80% of iron ore production in Iran).

- Chadormalu Mining and Industrial Company produced 9,498,000 mt of iron ore. It is the largest iron ore producer listed on the Tehran Stock Exchange,

- Gol Gohar Iron Ore Company produced 7,209,000 mt of iron ore; Gol Gohar pellet plant near the southern city of Sirjan, the biggest of its kind in the Middle East, uses iron ore concentrates from the Gol-e-Gohar mine in the province. The new plant produces five million tonnes of iron ore per year; enough for production of 2.5 million tonnes of steel.

- Iran Central Iron Ore Company produced 5,310,000 mt, with the remainder produced by other smaller public sector miners. In 2009, Iran exported about 10 million metric tons of iron ore, mainly to China.

In 2012, Iran opened a sponge iron plant in Hormozgan Province with a projected annual output of 1.8 million tons. Tariffs for the export of iron ore concentrate and pellet have been set at 50% and 35% respectively (2010).

Steel

Mobarakeh Steel Mill in Esfahan is Iran's largest steel mill.

Mobarakeh Steel Mill in Esfahan isIran's largest steel mill.

Steel production capacity will reach 17 million tons from 10 million tons in 2009 after the private and state projects come on stream, and 40 million tons in 2012. Main steel mills are located in Esfahan and Khuzestan.

Major raw steel producers in Iran are:

- Mobarakeh Steel Mill (47% market share as of 2010),

- Khouzestan Steel Company (23% market share, with new capacity of 80,000 tons).

- Isfahan Foundry (20% market share),

- Iran National Steel Industries Group (10% market share),

Other notable or new steel producers in Iran are:

- Azerbaijan Steel Company,

- Iran Steel Alloy Company,

- Ahvaz Pipe and Rolling Company,

- Khorasan Steel Company,

- Natanz Steel Complex, near the city of Isfahan with annual production capacity of 800,000 tonnes of steel rods and is the largest steel rod plant in the Middle East.

- Bonab Steel Complex, in the north-western province of East Azerbaijan. The first unit is a corrugated steel bar production line, with a production capacity of 1 million tonnes per annum and is the largest of its kind in the Middle East. The second unit is a steel ingot production plant, with an annual capacity of 500,000 tonnes.

- In 2010, Iran also inaugurated the largest galvanized sheet production plant for automobiles in the Middle East in the city of Shahrekord. The plant, which was financed byIran Khodro and Saipa group, has a capacity of 400,000 tpy.

- In 2012, a steel ingot plant was inaugurated in Hormozgan province of Iran. The Hormozgan Steel Company has the initial production capacity of 1.5 million tons per year with the capacity to be extended to three million tons in a year. The plant has been built by an Iranian-German consortium (IRITEC, SMS-DEMAG).

Iran became self-sufficient in steel production in 2009. In 2008 Iran produced 7.5 million tons of direct reduced iron (DRI). It produces 13 percent of global DRI production and 41 percent of total Middle East DRI production. In addition, these projects have resulted in industrial decentralization, development of underprivileged regions, increase in GNP and promotion of industrial infrastructure. Iran is the world's 16th steel producer.

Bauxite and aluminium

Bauxite

In 2009 Iran will produce 230,000 tons of bauxite.

Aluminium

Iran's aluminium production is targeted to exceed 400,000 tonnes in 2012 and 1.5mnt by 2022. Planned projects include Alumina Mine's 100,000tpa aluminium production project in North Khorasan, 276,000tpa South Aluminium project as well as the 375,000tpa Khuzestan Aluminium project. As at 2012, the largest plants for aluminium production in Iran are:

Iralco,

Almahdi,

Hormozal aluminium smelter plant in Bandar Abbas. The newly built Hormozal plant with an annual production capacity of 147,000 tonnes is a joint venture between Iran and Italy.

Coal

Iran has recoverable proven coal reserves of nearly 1.9bn short tonnes, and with total estimated coal reserves of more than 50 billion short tonnes. By mid-2008, the country produced about 1.3m short tonnes of coal annually and consumed about 1.5m short tonnes, making it a small net importer of coal. Iran plans to increase hard-coal production to 5 million tons in 2012 from 2 million tons in November 2008. Major coal producers and exporters in Iran are:

Kerman Coal Company,

Eastern Alborz Coal Company, and

Central Alborz Coal Company.

Coke

In 2009 Iran will produce 1.7 million tons of Coke.

Zinc and lead

Iran has over 220 million tonnes of proven zinc and lead ore reserves. With approximately 11 million tonnes of zinc metal constituent and 5 million tonnes of lead metal constituent, Iran has just below 5% of the world’s metal constituent reserves. Two important mines in Iran are:

Mahdi-Abad, which has 75 million tonnes of ore with a zinc concentration of 6% and a lead concentration of 2.7%,

Angouran mine, which has 16 million tonnes of ore with a zinc concentration of 26% and a lead concentration of 6%.

In 2009, with approximately 165,000 tonnes of production, Iran ranked first in the Middle East and 15th in the world in terms of zinc and lead production. In 2009, Iran exported 77,000 tonnes of zinc and lead concentrate and ingot.

The largest or most profitable producers of zinc and lead in Iran are:

Iran Zinc Mines Development Group (largest producer),

Bama Mining & Industrial Co.,

Bafgh Mines Co.

Kalsimin Co. (the largest zinc producer in the Middle East)

Uranium

Iran is believed to have large reserves of uranium to use as nuclear fuel in different parts of Iran including Bandar Abbas, Yazd, North Khorasan and Iranian Azarbaijan.

Copper

In 2009 Iran will produce 383,000 tons of copper. As of 2011, Iran had the world’s 9th largest reserves of copper at 32.5 million tons.[58] The mines at Sar Cheshmeh in Kerman Province contain the world's second largest lode of copper ore (5% of the world's total). As of 2010, Iran ranked 10th in copper production and 17th in copper cathodesproduction (220,000 tons).[59] In 2009, Iran exported $1.2 billion worth of copper cathodes.[59] National Iranian Copper Industries Company (NICICO) is one of the largest companies listed on the Tehran Stock Exchange and was the largest non-oil exporter in Iran in 2010 with exports worth $1.3 billion.

Gold

Iran's total gold reserves (below ground) are estimated at 320 metric tons. Based on a short-term program (2008), gold production will reach five tons per year. Under the long-term plan, the figure will rise to 25 tons per annum. The main gold-rich regions in Iran are:

Meydouk in Shahr-e Babak (Kerman Province),

Khorapeh in Piranshahr (West Azerbaijan),

Nabijan in Kalaybar, (East Azerbaijan Province)

Andaryan in Varzaqan County, East Azerbaijan Province

Alikh in Jolfa (East Azerbaijan Province),

Logheh (Zanjan Province),

Qolqoleh (Kurdestan Province),

Saqqez, in the west,

Piranshahr in the west,

Maherabad, in the east,

Sheikhabad, in the east.

The gold mine in the city of Takab in the West Azarbaijan province (Iran's largest Gold mine until 2012) has over 4 tons of proven gold reserves and 5.81 grams of gold can be netted from each ton of gold ore extracted from the mine. In 2012, three new gold mines with 16 tons of proven net gold deposits have been discovered in Saqqez city in the western province of Kurdistan.

Cement

In 2009, IMIDRO reported that 9 countries including Syria, Venezuela, Bolivia, Algeria, Lebanon, Ecuador, Iraq, Belarus and one of the Mid-Asian countries will have cement plantswhich will be constructed by Iranian engineers. Iran is the 8th cement producer in world and 2nd in the Middle East, after Turkey. In 2009 Iran produced some 65 million tons of cement per year and exported to 40 countries. There are 57 active production units in Iran as of 2010. As of 2010, 28 cement companies were listed on the Tehran Stock Exchange. Iran constitutes 1.8% of the world’s cement production and 1.6% of the world’s cement consumption. The main producers of cement are:

- Fars & Khuzestan Group is Iran’s largest producer of cement with a market share of 24%,

- Abyek with 8% market share,

- Tehran with 7% market share,

- Sepahan with 6% market share.

Cement production/prices in Iran are being liberalized since 2008. The cement industry is one of the economic sectors that will be hit the hardest in Iran following of the 2010 subsidy reform plan, because many Iranian cement factories are energy inefficient.